Can Rinsers

Solve the Can Line Bottlenecks

Increase Can Flow and Line Speed

Eliminate Manual Changeovers

Increase Service

Life

Decrease

Downtime

Pure by Design

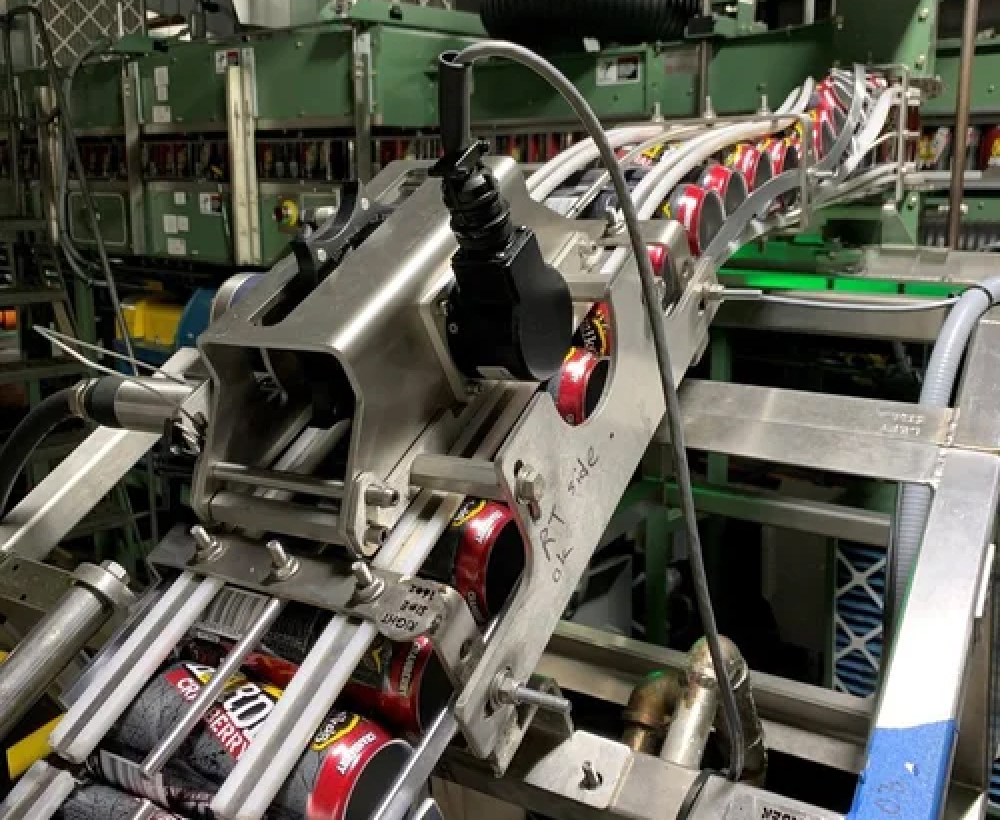

You already know the importance of a clean can. Your customers can taste the difference. At Entech, we don’t just share that expectation; we’ve built our entire approach around it. Entech’s premium can rinsing systems leverage patented technology for ultra-fast changeovers, engineered to meet your line’s unique production demands with precision, purity, and longevity. And because consistent performance is just as critical as initial specs, every Entech rinser is backed by our Rinser & Twist Inspection Program—an annual, onsite performance tune-up that helps protect your investment and identify wear before it becomes downtime.

Advanced Purity Technology

Our patented Gatling Gun® Ionized Air Rinser and Quick Change™ Rinser combine precision engineering with long-lasting design.

No Air, No Errors

Entech rinsers eliminate pneumatic changeovers, removing the inconsistency, downtime, and errors common with air-driven systems. Our mechanical, tool-less design with locking mechanical setpoints and permanently mounted twists ensures fast, precise, and repeatable changeovers without misalignment or lost parts.

The result?

With routine inspection included through our Rinser & Twist Inspection Program, we help keep those outcomes consistent—year after year.

Gatling Gun® Ionized Air Rinser

High-speed automation combined with enclosed, filtered rinsing ensures every can is clean, safe, and production-ready. The Gatling Gun’s patented rotating turret stores multiple twist fittings, which eliminates the need to store and manually change fittings.

What sets the Gatling Gun® apart?

Ready for Next Level Purity™?

Entech rinsers are custom-engineered for your line specifications and future needs. Whether you’re adding

new can sizes, upgrading to sustainable air rinsing, or increasing throughput, we’ll deliver a solution built for

your operation.

And we’ll help you maintain it - with annual onsite

inspections to ensure your rinser and twist systems

keep performing to spec.

Entech rinsers are custom-engineered for your line specifications and future needs. Whether you’re adding new can sizes, upgrading to sustainable air rinsing, or increasing throughput, we’ll deliver a solution built for your operation.

And we’ll help you maintain it - with annual onsite inspections to ensure your rinser and twist systems keep performing to spec.